The high resilience introduced by its thickness can proficiently take in affect and defend the adhered from hurt.

Remark: The above complex parameters only served as regular or agent, and don't represent any warranty or obligation&interval;

These Qualities also ensure it is suited to use in electrical insulation of wires and cables. In addition to Digital purposes, these goods may also be Employed in transportation machines and packaging purposes.

A:Warmly welcome, we can easily explain to you our firm and hope for a long time corporation with you&period of time;

Employed for solar photovoitaic battery cells sealing and mounting, modules as well as other components mounting and sealing.

three. All of carton box is going to be put on one non-fumigation pallet, then all carton packing containers might be wrapped by film.

We aims at offering you with high excellent products and solutions with well heat resistance and strong longevity which is easy to procedure. Welcome to get tapes with us at competitive price.

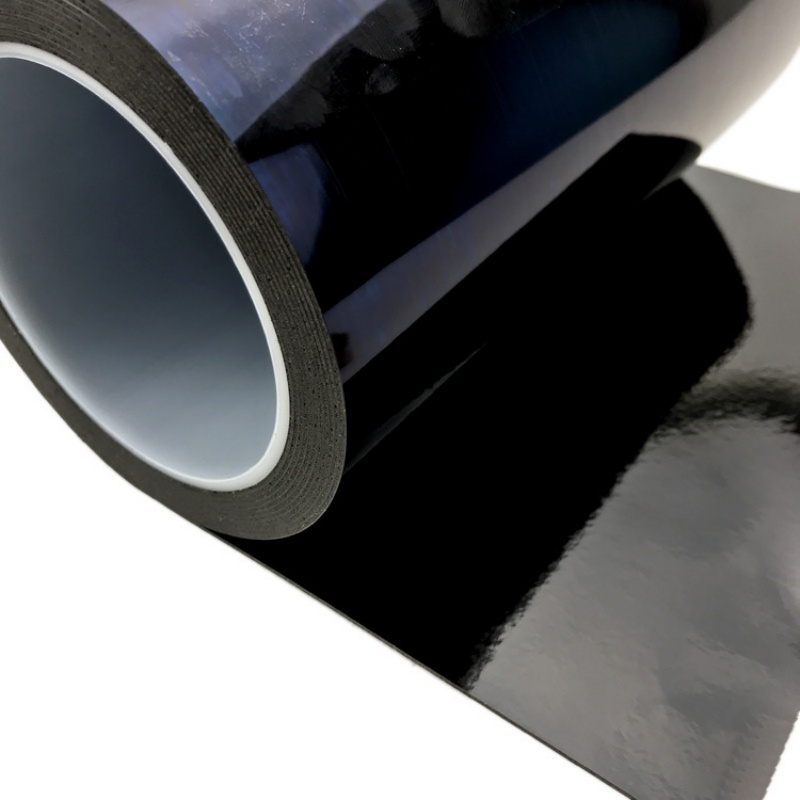

Single-sided EVA foam tape: just one side is sticky, and another side is foam substance. Single-sided EVA foam tape is mainly used in events wherever one side has to be fastened and the other side has to be buffered or shockproof.

The sawing system is especially employed by us to chop custom foam sheets, blocks and strips. It is a really helpful and successful solution to fabricate the EVA foam products. After having EVA foam sheets of wanted thickness through skiving, our factory staff will manipulate the foam sawing equipment to chop the foam sheets to ideal size High Viscosity Double Sided Foam Tape PE Foam Tape Sponges Soft Mounting Adhesive Tape and width. The sawing approaches are confer with 2 methods, 1 is vertical sawing and the other is horizontal sawing.

You can see die cutting are Utilized in many industries like paper packaging wherever individuals make use of the metal designed die for chopping out paper box. We use the die reducing precisely the same way for foam fabrication. To fabricate custom foam pieces, die cutting is often utilized for EVA foam packaging, foam scenario inserts, foam profiles, foam gaskets and pads. The key parts for utilizing foam die-reducing is we have to make a decision the right CAD drawings for custom foam sections.

By exploiting foam fabrication abilities In particular foam thermoforming and lamination, EVA foam substance is often processed as quite a few 3D foam pieces and factors.

Our young, energetic, and industrious team usually rapidly respond to customer needs with practical solutions. Digging into the foam industry, our team can always deliver the most helpful know-how for customers jobs.

Thermoforming as You may even see pretty much is related to heating and temperature. Our technicians will work cautiously to adjust the termoform machines with appropriate heat temperature and pressure. The custom EVA foam parts will be formed in the mould less than heating and tension. A lot of 3D foam pieces are applying foam thermoforming system to obtain together with boat seat cushion together with other custom foam sections.

Right after a particular timeframe our operator arrange before, the processing from the raw components might be concluded.